Salcey Precision Engineering invests to stay ahead

Recent investments in sophisticated multi-axis machine tools and high-level Mitutoyo metrology equipment at Salcey Precision Engineering of Hartwell, Northamptonshire, mean customers in demanding industry sectors such as aerospace and motorsport can be assured of receiving components of exemplary dimensional accuracy and geometric conformance. The firm has a well-founded belief in technological development and investment to keep ahead of the game, and sees its future in delivering complex machined parts quickly for demanding customers who require a high standard of quality.

Salcey Precision, a quality-led ISO9001 company, is now one of the largest subcontract engineering companies in the county and has recently become heavily involved in the manufacture of components for the medical industry, in addition to maintaining its tradition of quickly delivering tight-tolerance, high-quality machined parts in the time-driven environment of the F1 motorsport and aerospace industries.

Speed is of the essence

A typical instance of the need for speed is a supercar engine component currently in manufacture. As machine tools were acquired to boost production capacity to meet the target volumes on this part, and to meet particularly tight tolerances specified on some angular features, it was planned to ensure that fast, accurate and reliable inspection equipment was simultaneously obtained so as to be able to confirm conformance to specification.

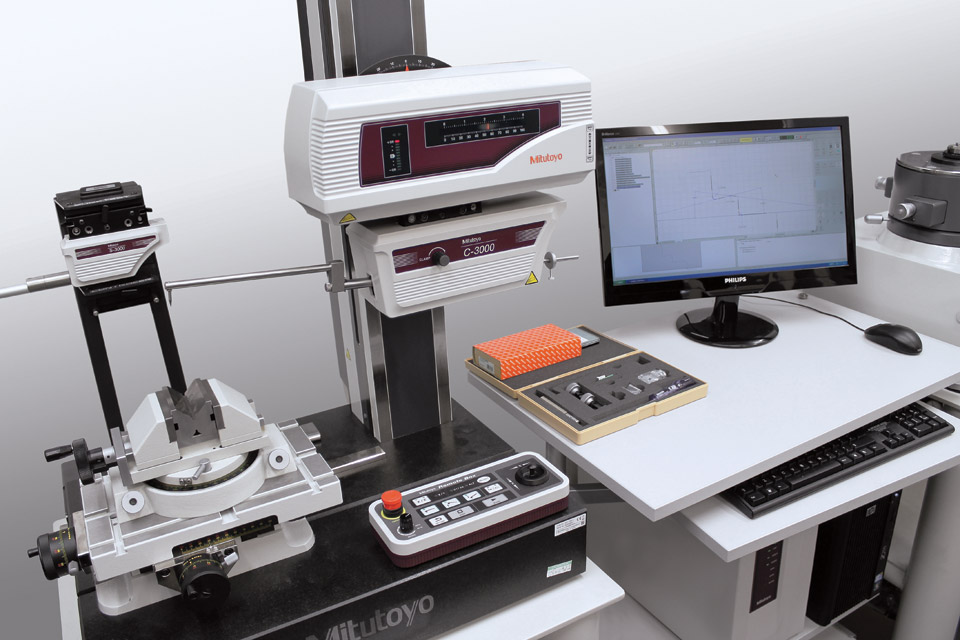

Richard Alcock, Salcey’s Managing Director, remarked: “We typically work to less than 10 microns and so we have to check output on CNC type CMMs frequently to make sure we are maintaining these tight tolerances.” After looking at a number of leading metrology vendors the company chose Mitutoyo to supply three major products: a Crysta-Apex S574 Coordinate Measuring Machine (CMM), an SV-C3100 Formtracer and a Roundtest RA-2100.

Richard Alcock, Salcey’s Managing Director, remarked: “We typically work to less than 10 microns and so we have to check output on CNC type CMMs frequently to make sure we are maintaining these tight tolerances.” After looking at a number of leading metrology vendors the company chose Mitutoyo to supply three major products: a Crysta-Apex S574 Coordinate Measuring Machine (CMM), an SV-C3100 Formtracer and a Roundtest RA-2100.

Enhanced measurement capability

Dave Hammond, Quality manager at Salcey says: “We needed a higher standard of inspection for a new motorsport part, in particular excellent scanning measurement capability, so the CMM was bought-in equipped with a leading-edge scanning probe system. Similarly, the Roundtest was needed to check cylindricity on another critical motorsport component. The Formtracer allows us to measure complex contours and surface finish more comprehensively than before.” All this new equipment meant that the inspection room had to be redesigned, but now the company is in the happy position of being able to offer a subcontract measurement service for complex and tightly toleranced machined parts using the spare capacity of this new suite of measuring machines.

Sound advice and solid support

Mitutoyo’s Mark Boylin, Technical Sales, remarked: “I believe that during the procurement process Salcey Precision came to appreciate the value of sound, honest advice regarding suitability of a particular measurement solution to the company’s range of product, which is something we at Mitutoyo provide to all our customers. This advice is generally backed up by demonstrations of the equipment in action measuring the customer’s typical parts and in this case Simon Elliott, our Special Products Division Manager and Bernie Hall, one of our CMM Technical Specialists, provided comprehensive demonstrations both at our Coventry Showroom and at our Halifax Sub-Contract Measurement Facility.”

Dave Hammond commented: “We had excellent support during purchase, installation and training. All Mitutoyo personnel were very helpful and nothing has been too much trouble. We have total confidence in our measurement results and this in turn gives our customers confidence in the products we are supplying. I’m sure this factor has increased our order book.”