The ‘Apex’ of Mitutoyo Precision for Qualiturn

Hertford based Qualiturn Products Ltd a perfect example of the productivity increases that can be achieved by the application of advanced IT systems, the use of high-yield machine tools and the adoption of cutting-edge automation technology. In addition to performing day-time manufacturing, the business’ highly efficient working practices allow it to operate ‘lights-out’ throughout each night.

Qualiturn has achieved a genuine ‘virtuous circle’. The company’s application of advanced manufacturing techniques has enables it to realise world-class levels of production efficiencies. These efficiencies have allowed the business to supply very competitive quotes that have resulted in further profitable business. And the profits generated have supported further investments in ever more advanced manufacturing technologies.

In addition to earning an excellent reputation for efficiency, another important aspect of Qualiturn’s values can be found in the company’s title. Qualiturn’s quality philosophy is reflected in all aspects of its activities. Although, as often happens to business’ that achieve substantial upturns in production, the increased amount of Qualiturn parts needing final inspection, began to place a strain on the company’s quality control provision.

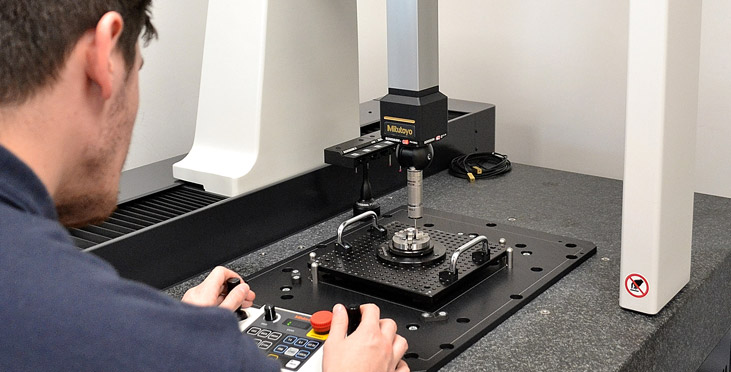

To ensure the continued efficient operation of the business’ inspection department, Qualiturn’s Managing Director, Nick Groom recently undertook a search for a Coordinate Measuring Machine (CMM) that had a precision specification that would enable the accurate inspection of parts with demanding dimensional tolerances. Also, given the high volumes of components that need to be inspected, a fast operating, CNC driven machine, with a granite table that could accommodate multiple components, was required.

Having studied the available alternatives, as it met all of his criteria, Nick Groom purchased a 500mm x 700mm x 400mm - x,y,z capacity version of Mitutoyo’s recently launched CRYSTA-Apex V series CMM. As a result of increased acceleration, faster travel and improved accuracy specifications, the advanced new CRYSTA-Apex V series CMMs are able to accomplish significantly more component measuring cycles in each working day and also deliver higher levels of precision.

Explaining Qualiturn’s quality ethos and his recent Mitutoyo CMM purchase, Nick Groom said. “We are a BS EN ISO 9001: 2015 registered business and we see efficiency and quality as the same thing. For instance, the right-first-time production of quality parts is efficient, whereas, the manufacture of poor quality parts that require rework is inefficient.

“Having recently searched for a suitably accurate and fast acting CMM, when compared to the alternatives that I considered, I was impressed with the abilities of Mitutoyo’s new CRYSTA-Apex V series machines and was happy to place an order.

“Now installed and up and running, following a short operator training session, our staff soon mastered the new CMM’s logical software and controls. As well as having the levels of precision that allow the inspection of our most demanding parts, our CRYSTA-Apex V series CMM has the speed of operation that we need, and it has significantly increased our inspection efficiency levels.

“Now, prior to a production run, when writing a program for our machine tools, we use this model to also generate an inspection program for our new Mitutoyo CMM. This means that when manufacturing commences, we can load the relevant program onto our new CMM and quickly verify the first-off part. Then, throughout the production run our quality staff are able to load large batches of parts onto the CMMs bed and start a fully automated, un-maned inspection routine.

“The impressive performance of our new Mitutoyo CRYSTA-Apex V series CMM means that, not only has it satisfied our current inspection requirements, but it should also be able to meet all of our future anticipated inspection needs.”

Drawing on its technological expertise in the field of CMM design and manufacture, Mitutoyo recently launched the CRYSTA-Apex V Series of high-accuracy CNC Coordinate Measuring Machines. The new CMMs have a proven bridge-type construction, they feature high-rigidity air-bearing guiding on every axis and use Mitutoyo’s world-renowned ABS scales.

As the successor to the previous generation of CRYSTA-Apex CMMs, the new models build on the merits of their globally popular predecessors. In addition to boasting impressive accuracy specifications, the new Mitutoyo models have rapid acceleration and fast speed characteristics. Not only do these qualities allow the inspection of components with challenging dimensional specifications, when compared to other less able machines, they increase business’ efficiency levels by enabling more components to be inspected in a given time.

Increasingly, businesses are looking to measure parts closer to their means of manufacture, therefore, besides being ideal for use in inspection departments, CRYSTA-Apex V Series CMMs have a high level of resistance to environmental conditions and are perfectly at home in less than ideal production environments. Further aiding shop-floor use, the new CMMs are equipped with an automatic temperature compensation feature.

As a result of Mitutoyo’s flexible CMM concept, the new CRYSTA-Apex V Series represents a genuine future-proof investment. In addition to handling users’ current inspection needs, thanks to the ability to change or add probe systems, accessories and software, the new CMMs are capable of adapting to future requirements.

Also, given the advent of Smart Factories and the arrival Internet of Things (IoT), the advanced CRYSTA-Apex V Series CMMs are equipped with Mitutoyo’s Smart Measuring System (SMS) technology. SMS allows the online monitoring of the CMMs’ operational status and the capture of records related to key parts.

Moving forward, Mitutoyo will drive the installation of SMS technology, not only in CNC CMMs, but also in other CNC measuring instruments. Leveraging IoT, Mitutoyo will support the realisation of smart factories that conduct the sophisticated management of information relating to production and quality.